At Roedan, we know that building trust in a product starts long before the customer gets their hands on it. That is why, as part of our system engineering philosophy, we champion traceability of everything from the inception of a project through to delivery to the end customer and beyond. Part of this traceability includes us making sure that every product that we manufacture goes through a robust, in-house designed, end-of-line test system. Not only does this ensure that we can efficiently test hardware before shipping, but it also means we can get 100% test coverage and, importantly, record everything related to a test.

This gives us confidence that each unit leaving our doors meets the high standards we set for ourselves and our customers, and its importance was proven in practice when one of our customers experienced issues with returned PCBs, which had been tested and delivered late last year, that appeared to have faults before being assembled.

Naturally, this raised our attention, but because this particular run had been used to validate our automated end-of-line testing system, we knew the boards had been through both rigorous automated checks and, because we were being super vigilant to make sure the test was correct.

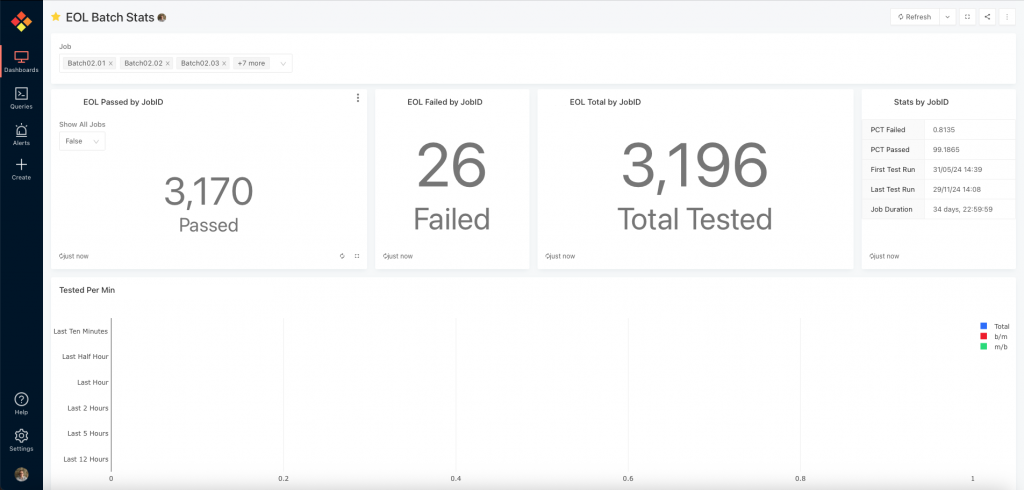

(Testing results)

The real advantage came from the detailed records we keep. For each of the 3,000 boards in that run, we captured data such as voltage and current behaviour, programming time, antenna performance, audio analysis, and the exact time and station of testing. Having this information allowed us to work closely with our customer to review what happened, trace each unit, and quickly identify that the boards were performing correctly when they left testing.

What we found was reassuring: the challenges weren’t in the boards themselves but potentially in the assembly later on. With some remedial work to fix the issues caused by assembling the units were quickly brought back into service. More importantly, the process showed the value of accurate test records – they not only speed up problem-solving but also give both Roedan and our customers full confidence in the products we deliver.

At Roedan, we see testing as one of the most important parts of our work. Our goal is to give customers visibility, reassurance, and support at every step of the journey. If you’d like to learn more about how our testing processes can bring greater confidence to your projects, we’d be happy to have a conversation and showcase real use cases.