The Internet of Things (IoT) is transforming industries worldwide, including in the UK, with applications ranging from smarter cities and optimised transport systems to precision agriculture and real-time environmental monitoring. Yet, despite its enormous potential, one of the biggest challenges for widespread IoT adoption is power consumption. The reason for this is that many devices must operate in remote or hard-to-reach locations, where frequent battery replacements are simply not practical. This makes ultra-low power design not just desirable, but indeed very important.

To achieve it, engineers need to think beyond simple hardware choices. Success lies in a holistic approach that carefully considers hardware design, software optimisation, communication strategies, and environmental factors.

Smarter Hardware Choices

The foundation of ultra-low power IoT design starts with hardware. Devices must be designed to consume power only when needed, switching components on and off dynamically. Features such as dynamic power control, where processors ramp up or down their speed depending on workload or shut down entirely until triggered by an event, can dramatically extend device life.

A common mistake in device design is allowing processors to sit idly waiting for communications. A better approach is to adopt event-driven design, putting the system into low-power modes and only waking it up when necessary. This principle also applies to memory use: storing data in volatile memory forces the system to remain powered, while writing critical data to non-volatile storage allows the processor to shut down fully and restart from scratch when required. The trade-off is that deeper sleep states extend wake-up times, so designers must balance energy savings against responsiveness.

Software Efficiency and System States

Modern processors are capable of multiple low-power states, ranging from partial sleep to “system off” modes where almost everything is powered down except for essential wake-up triggers. Efficient use of these modes requires code that can restart smoothly, sometimes as if the device is booting from new each time.

Software also has a major role in reducing unnecessary power draw. Instead of transmitting data continuously, devices can be programmed to send updates only when meaningful changes occur. Data compression, lightweight communication protocols, and batching transmissions are simple but highly effective strategies. Since communication typically consumes the most energy, minimising transmission frequency and size has a direct and measurable impact on battery life.

For ultra-low-powered systems, there is a trade-off between communication, processing time, and where decisions are best made. Using features such as AI at the edge can help delay when data is sent or vastly reduce the amount of data to be sent, thereby reducing both bandwidth and energy requirements. For example, in the UK, smart cameras deployed for wildlife monitoring in remote conservation areas use on-device AI to distinguish between species before sending updates. This ensures that large volumes of unnecessary raw video data are not transmitted, conserving both energy and network resources. Such approaches not only improve efficiency but also extend device lifetimes in challenging, often off-grid environments.

Communication Strategies in Context

Communication protocols make or break an ultra-low power strategy. In fact, the UK benefits from a wide range of low-power technologies such as NB-IoT, LTE-M, and LoRaWAN. Each has trade-offs: NB-IoT and LTE-M can be efficient for infrequent data, whilst technologies such as CAT-1 Bis may better support devices needing higher throughput despite their higher instantaneous current draw.

Crucially, “low power” does not always mean choosing the protocol that uses the least energy per second. In some cases, a higher-power connection that transmits data quickly and then powers down completely is more efficient than a lower-power protocol that requires longer active periods.

Marginal Gains that Add Up

Ultra-low power design rarely comes from one big optimisation. Instead, it results from small, cumulative improvements – so-called “marginal gains.” Examples include driving LEDs at the lowest visible brightness using pulse-width modulation, configuring input pins correctly to prevent current leakage, or powering down voltage measurement circuits until needed.

The efficiency of power supplies and supporting components matters just as much as the core processor. Choosing a more efficient power supply or a module designed for low-power states may cost more upfront, but can yield significant savings over the lifetime of the device. Over years of operation, those savings translate directly into longer battery life and lower maintenance costs.

Environmental and Battery Considerations

Battery chemistry is another decisive factor. Different applications demand different approaches depending on current draw, recharge cycles, and environmental conditions. For example, a sensor that transmits once a day can run for years on a small lithium cell, while a device with frequent high-current bursts may require chemistries designed for pulse loads.

The UK’s climate adds further complexity. Devices must be able to operate efficiently in cold, damp conditions as well as during summer heatwaves. Combining batteries with renewable energy sources such as small solar panels or energy harvesting circuits can provide resilience, ensuring devices remain operational even in challenging conditions.

A Choreography of Components

Achieving ultra-low power in IoT devices is ultimately about orchestrating all system components into a finely tuned balance. Hardware, software, communications, and energy storage all need to work in harmony to deliver functionality while consuming as little energy as possible.

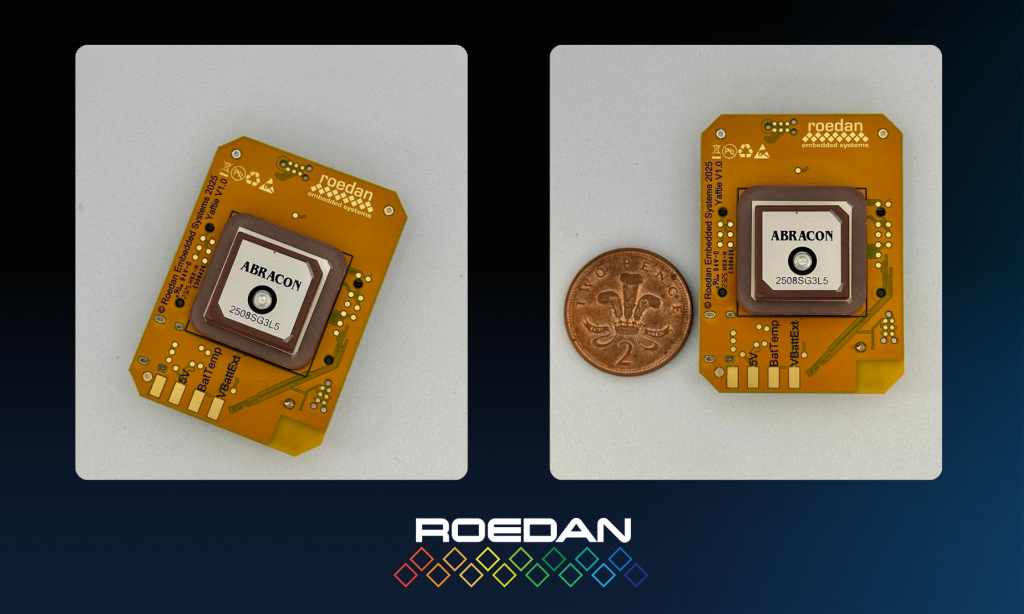

(Yaftie Board is part of Roedan’s Ultra Low Power Fusion Platform. It brings together efficient power management, advanced connectivity options, and intelligent on-board processing—all within a footprint of just 40mm x 55mm)

When these elements are carefully balanced, the results are impressive. Devices can run maintenance-free for up to a decade on a single battery or remain operational in remote locations for years without intervention. For industries in the UK and beyond, this level of reliability is not just a technical achievement—it is the key to unlocking the full potential of the Internet of Things.